Sensor IT Completes Open RAN Smart Manufacturing Project

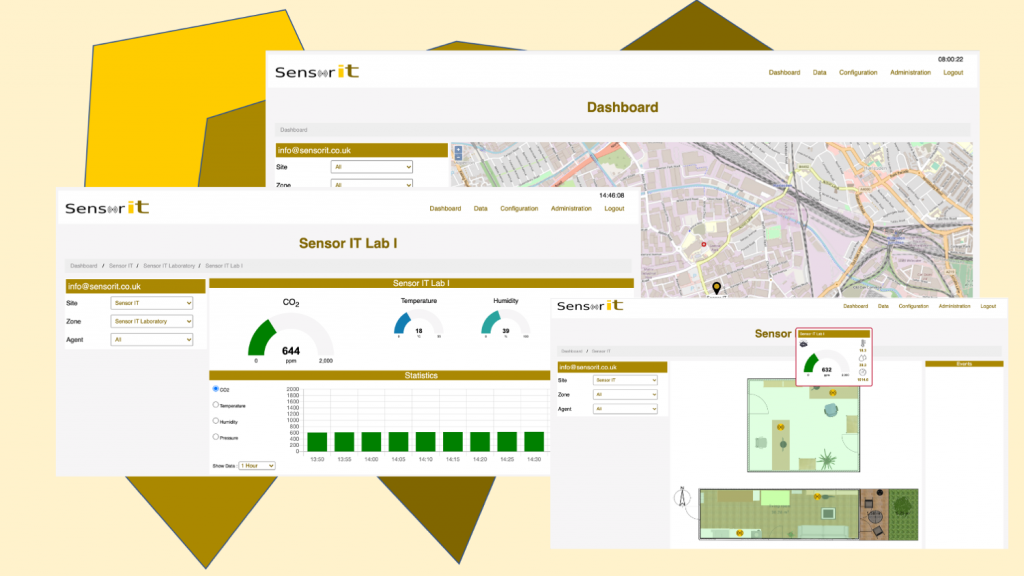

Open RAN Smart Manufacturing As industries accelerate toward the Fourth Industrial Revolution, Open RAN Smart Manufacturing stands out as a cornerstone of digital transformation. Factories are becoming increasingly interconnected through Internet of Things (IoT) sensors, AI-driven automation, robotics, and real-time data analytics. To support these technologies at scale and with high reliability, advanced wireless connectivity is essential. This is where Open RAN (Open Radio Access Network) comes into play—offering a flexible, cost-effective, and innovation-friendly approach to wireless infrastructure. What is Open RAN Open RAN decouples hardware and software in cellular networks, allowing components from different vendors to interoperate using open standards. Unlike traditional RAN systems that are vertically integrated and vendor-locked, Open RAN introduces modularity and interoperability. This has profound implications for smart manufacturing environments, which demand adaptable, secure, and high-performance networks. Customizability for Factory NeedsSmart factories are dynamic and often require customized network configurations to support various applications, such as predictive maintenance, machine vision, or augmented reality for training and diagnostics. With Open RAN, manufacturers can tailor network parameters to specific zones—such as giving higher priority bandwidth to robotic assembly lines while allocating lower latency channels to quality control areas. This level of granularity is difficult to achieve with closed, monolithic RAN systems. Reduced Costs and Faster InnovationBy breaking the dependency on single-vendor solutions, Open RAN reduces the total cost of ownership. Manufacturers can source components from multiple vendors, avoiding high licensing fees and vendor lock-in. This also fosters innovation: smaller vendors specializing in AI-based network optimization or energy-efficient radio units can now contribute to the ecosystem, pushing the boundaries of what’s possible in wireless communication inside industrial facilities. Enhanced Network AgilitySmart manufacturing thrives on agility—factories must rapidly adapt to changes in demand, supply chain disruptions, or product design. Open RAN’s software-centric nature enables faster deployment and reconfiguration of network services. For instance, during a shift in production lines or floor layout, network functions like signal coverage, slicing, or interference management can be adjusted virtually without needing to overhaul physical infrastructure. Improved Security and MonitoringSecurity is a critical concern in industrial environments. Open RAN architecture allows for better visibility into the network, enabling tighter security controls. Manufacturers can integrate threat detection software directly into the RAN layer or isolate parts of the network to contain potential breaches. This level of transparency and control is invaluable in protecting intellectual property and ensuring operational continuity. Future-Proofing with AI and Edge ComputingAs AI and edge computing become standard in manufacturing, Open RAN provides an ideal platform for integration. AI-driven network functions can analyze traffic patterns in real time and optimize performance, while edge computing units can be co-located with Open RAN nodes to reduce latency. This synergy supports advanced use cases like real-time machine diagnostics or autonomous guided vehicles (AGVs), which require near-instantaneous data exchange. Sensor IT and Open RAN Smart Manufacturing At Sensor IT, we empower manufacturers with cutting-edge Open RAN-based Smart Manufacturing solutions, enabling seamless connectivity, automation, and real-time data intelligence. Imagine a factory where machines, sensors, and robotics communicate effortlessly, optimizing production with minimal downtime. Our Open RAN technology provides a flexible, scalable, and cost-efficient private 5G network, ensuring ultra-low latency and high reliability for mission-critical operations. By integrating AI-driven analytics and IoT connectivity, we help clients achieve predictive maintenance, enhanced security, and maximum operational efficiency. With Sensor IT, manufacturers break free from vendor lock-in, customise their network infrastructure, and future-proof their smart factories for Industry 4.0 success. Having been granted a 5G licence by OFCOM, Sensor IT can be your innovation partner when it comes to deploying low cost private Open RAN networks. Get in touch. We can help.

Sensor IT Completes Open RAN Smart Manufacturing Project Read More »